micro hardness testing method|vickers hardness test diagram : export Microhardness testing can be defined as indentation hardness testing that involves applied loads of 1 N or less on the indenter or, more precisely, as tests which result in indentation depths of <70–100 μm. Autoclaves are extremely powerful and can be a bit intimidating to those who are inexperienced with operating them, which is why we’ve put .

{plog:ftitle_list}

✓Door handles ✓Door lock rod ✓Door lock assembly ✓Door gasket ✓Radial arms ✓Vertical door ✓Compressor ✓Power operation ✓Electric locks See more

Microhardness testing can be defined as indentation hardness testing that involves applied loads of 1 N or less on the indenter or, more precisely, as tests which result in indentation depths of <70–100 μm.

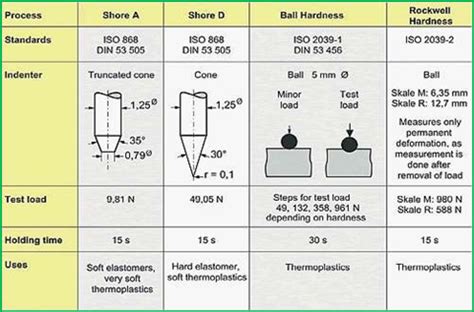

Micro hardness test is used for measuring the hardness of thin or small objects, complicated shapes, surface coatings, and plantings. This testing method can also perform for . In this article, we will take a look at micro hardness testing in more detail and will outline some of the leading applications of our flexible turnkey .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .following are the most common hardness test methods used in today`s technology: 1. Rockwell Hardness test 2. Brinell Hardness 3. Vickers Hardness 4. Knoop Hardness 3.1: Rockwell Hardness Test The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied.

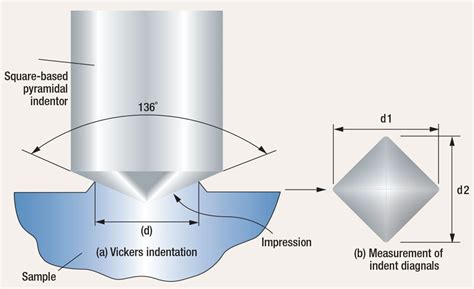

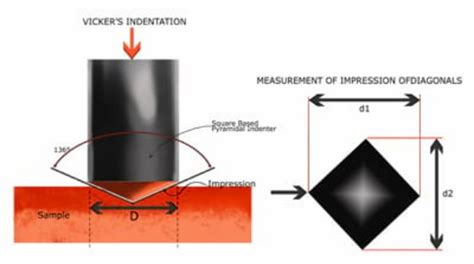

There are two main methods of microhardness testing, both offering repeatable and accurate results: Vickers hardness testing and Knoop hardness testing. Vickers hardness testing. The Vickers hardness test uses a Vickers indenter, which is shaped like a squat pyramid and is typically pressed into the surface of the material for 10 seconds. Micro vs. Macro Hardness Tester. Another common distinction is made between micro and macro hardness testing. Here, a basic differentiator is the application of lower loads and higher loads for different methods. Micro hardness testing involves applying a lower test load, typically ranging from a few grams to a few kilograms, while macro .

Micro Hardness Testing Methods 2.1 Vickers Micro Hardness Testing. The Vickers micro hardness test employs a diamond pyramid indenter, and the hardness is determined by measuring the diagonals of the resulting indentation. This method is widely used for brittle materials, ceramics, and thin films. . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is especially valuable for micro hardness testing requiring small, accurate measurements.

The Knoop hardness test method is usually done with lighter loads for microhardness testing and careful sample preparation is required. Knoop hardness testing is applied to samples needing indentations close together or on the edge of a sample, .

Small test loads < 0.2 kgf that produce tiny indents on the test pieces are typically used for micro hardness tests (the most commonly used method is Vickers). Hardness tests in the micro range may be applied to establish how hard the surface of thin coatings is or, for example, the hardness of individual crystallites or inclusions.The Vickers micro hardness test results of TRB in the two groups, which were carried out from thicker zone to the thinner zone and across the transition zone of each specimen cross-section as shown in Figs. 15.18 and 15.19.By contrast, all micro hardness profiles in the G1 specimens present the increasing trends from thicker zone (position 1) to thinner zone (position 5) except .Hardness test methods are methods for determining the hardness of a material. The hardness is an important mate- . Low-load and micro hardness testing machines – the DuraScan Series The pioneering standard load range is from 10 gf to 62.5 kgf and is applied with closed-loop

Standards and Methods. In hardness testing micro and macro, following the right standards ensures accuracy. For micro hardness testing, where small forces are applied, you need a fine metallographic finish. A diamond indenter creates tiny indentations, which are then measured with a microscope. Standards like ISO 6507, ASTM E384, and JIS Z2244 .Micro hardness, like Shore A and durometer tests, also measures indentation. . The slices were trimmed to a cylindrical or cube-shaped cross section of about 20 cm 2 before hardness testing. The slices were subsequently coarse polished and fine polished using emery papers and then dried. . The most common method to measure H is the Vickers .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be .When selecting a hardness test method, important considerations include: The type of material to be hardness tested; . Micro hardness testing Due to the lower loads used during hardness testing, micro hardness testing requires a polished or electropolished surface. It is important that the borders/corners of an optically evaluated impression .

In this paper, the Vickers and Knoop hardness test methods for the determination of microhardness are discussed and a simplified method for comparison of numerical hardness number values are presented. Microhardness testing enables the testing of thinner and harder.There is a great deal of confusion in conceptions about penetration hardness. Part of the problem results from a popular misconception that “hardness” is a basic property of a material. This is not the case. Hardness numbers are, more accurately, measures. Vickers: Appropriate for both macro and micro-hardness testing; it uses a smaller load than Brinell, which can range between 1kgf –100kgf . . The study presents experimental data comparing traditional and modern hardness . Finally, to show the usefulness of the Vickers micro-hardness testing method, the calibrated test method was applied on iPP with additions of carbon black up to 3 wt.%. Comparisons were made with data from the literature, but the hardness data generated in our work were found to be at least twice that reported in the literature.

while a micro test employs loads under 1kg. Another way to subdivide indentation hardness methods is based on the method of measurement. Brinell, Vickers, and Knoop values are derived from . determining the most applicable hardness testing method. • Hardness range of test material • Size and shape of the component • Degree of flatness .cally, for example, the test method, hardness value, tolerances, and an image of the indentation with measuring lines. This allows the operator to reassess . been completed and the sample removed from the hardness tester. Product Information ZHVµ-S Micro Vickers Hardness Tester PI 941 1219. Diamond Hardness Testing Software A: 201629 Start .

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low-load through to the macro range).Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work.We provide Microhardness Testing, this refers to indentation hardness tests performed by two common methods known as the Knoop and Vickers hardness test. ASTM E384 is the standard test method for Knoop and Vickers Hardness Testing of Materials. From the single Vickers test point to CHD testing The simple and efficient operation of our hardness testing machines is a focus of our development. For e.

Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three hardness testing load ranges: in the micro, low-load and conventional (macro) hardness range.

vickers hardness test diagram

early days of low-load (< 00gf) hardness testing, it was quickly recognized that improper specimen preparation may influence hardness test results. Most text books state that improper preparation will yield higher test results because the surface contains excessive preparation induced deforma-tion. While this is certainly true, there are other There are only two micro-indentation testers: Vickers hardness test and Knoop hardness test (9, 26) Which are suitable and practical methods for evaluating surface changes of dental hard tissues .

krautkramer branson portable hardness tester

Priorclave manufactures leading-class autoclaves and sterilizers, and distributes internationally. Select your region and see what Priorclave can do for you.

micro hardness testing method|vickers hardness test diagram